Description

Sen Tien Colors Your Life

Company Profile

- Established in 1956 in An-Ping Industrial District, Tainan, Taiwan.

- Initially produced PP wrapping materials and PP injection foils.

- Transformed into a leading heat transfer foil printing corporation in Taiwan.

- Second factory established in 2001; total production area of 6,600 square meters.

- 97 full-time employees supplying 70% of Taiwan’s market needs.

Heat Transfer Printing Technology

- Traditional silk screen printing limitations: low accuracy, time-consuming, high defect rate.

- Heat transfer printing: Graphics printed on heat-resistant plastic films, then transferred to product surfaces using heat transfer machines.

- Benefits: Delicate designs, rich colors, low defect rate, and long-lasting outcomes.

Product Categories

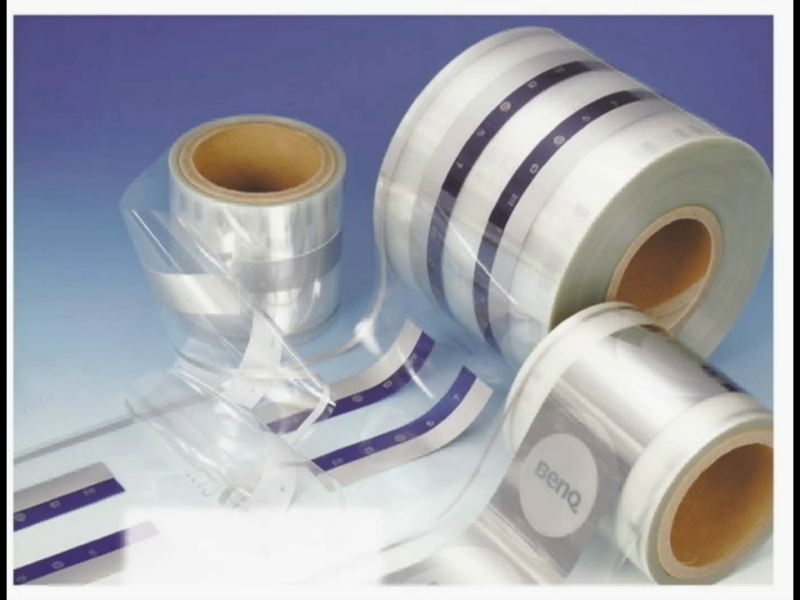

- General-purpose heat transfer foils:

- Applied to PP or PE goods (household appliances, cleanser and cosmetic containers, sporting goods, toys, stationaries).

- Injection foils:

- Suitable for tableware and sporting goods.

- Special effect heat transfer foils:

- Includes partly matte foils, vacuum electroplate foils, pearly or metallic ink foils, and metallic surface foils.

- In-mold transfer foils:

- Suitable for electronic appliances, automobiles, and motorcycles.

Market and Clients

- Advanced technology, unique inks, and strict quality control.

- Supplied to leading international companies: Disney, DELL, SIEMENS, Sanrio, KAO, UNILEVEL.

- 15% annual sales growth over the past five years.

- Major customers in Mainland China, Southeast Asia, and Central and South America.

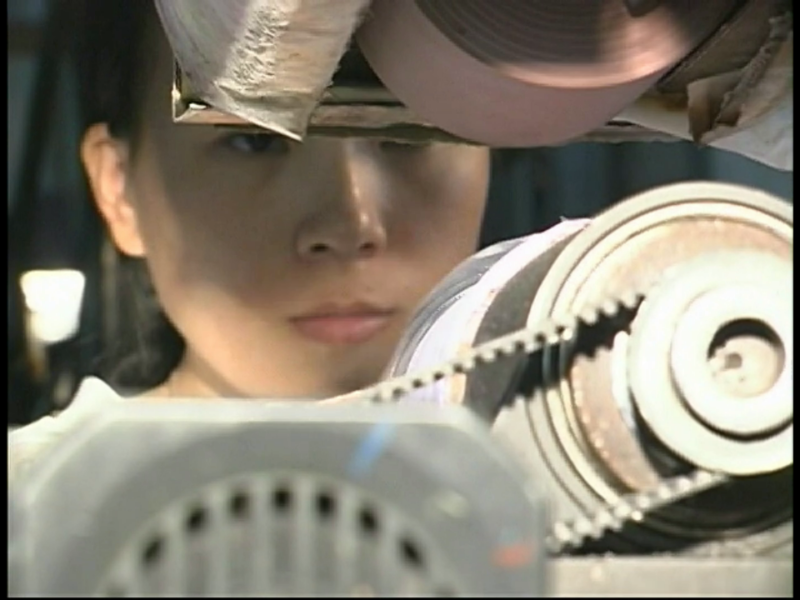

Computerized Production Lines

- Handles entire production process from customer’s graphic design to final printing.

- Professional publishing software for design adjustments.

- Plate Alignment Department for polishing and coating copper or chrome plates.

- Glyptographic machines for engraving plates.

- Printing Department for ink preparation and color matching.

- Five world-class rotogravure pressing machines (7-10 colors).

- Trimming foils into desired shapes and packing for shipment.

Quality Assurance

- QC inspectors monitor machine operations and check products before packing.

- Annual inspection by Disney Corporation for production quality.

Research and Development

- Focus on extending the applications of heat transfer foils.

- Japanese technical consultant aids in analyzing inks and materials.

- Laboratory tests for new coating procedures.

- Development of products to meet special customer requirements.

Scientific Management

- Employee growth between 10-20% annually since 1999.

- Average age of employees is 30.

- Computerized management of administrative matters, including working schedules.

- Management diagnosis plan and in-service staff-training program under expert guidance.

- ISO-9002 certification in 1998 and ISO-9001 (2001 version) in 2002.

Environmental Responsibility

- Complete recycling line for industrial wastewater, waste air, and waste ink.

- Facilities and processes meet national standards.

- Commitment to environmental preservation.

Looking Forward

- Dedication to excellent quality, work ethics, new products, and advanced management.

- Aim to contribute splendid and delicate decorative prints to everyday life.

Reviews

There are no reviews yet.